18mm lvl plywood for furniture and door core

Product Description

| LVL Plywood SPECIFICATION |

Product name | lvl plywood specification |

Material | poplar, hardwood,combi(poplar&hardwood),brich,finger joint core... |

Film | As request |

Thickness | 1cm-12cm or as your requirement |

Size | as your request |

Glue type | MR,WBP |

Boiling Time | 8hours,24hours,48hours,72hours(depend on type of glue) |

Moisture | 12%-17% |

Application | Package,pallets,planks. |

| Package | By break bulk or container |

Payment | T/T Or L/C at sight |

| Film faced plywood feature |

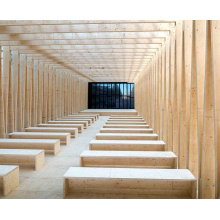

LVL is Laminated Veneer Lumber English abbreviation, is the raw materials as raw materials cut or cut into a veneer board, after drying, after coating, according to the simple pattern or most of the sequence of billet, and then by hot-pressing glued sheet The According to the use of materials can be divided into packaging LVL, furniture level LVL, construction level LVL; it has a solid wood sawn timber is not the structural characteristics: high strength, toughness, good stability , Accurate specifications, than the solid wood sawn in strength, toughness increased by 3 times.

LVL plate and solid wood sawn timber compared to the advantages: 1, LVL plate can be scarring scar, cracks and other defects scattered, staggered, thus greatly reducing the impact on the strength, so that the quality is stable, uniform strength, material variability is small, Is the best alternative to solid wood structural material; 2, the size can be adjusted, not the shape and defects of the wood, LVL plate up to 8 meters, the most thick up to 300MM, according to their own timber situation, select the size specifications 4, LVL with pest control, anti-corrosion, fire, water, etc., 3, LVL with the same processing, wood cutting, 5, LVL has a strong seismic performance and shock absorption performance and can resist the fatigue generated by periodic stress generated by fatigue; 6, this product is the first time in the production process of the corresponding pretreatment or the use of special adhesive; Green, non-polluting, the use of high-quality environmentally friendly adhesive in the production process; formaldehyde emission is far below the national standard, to meet the developed national standards, to ensure your health

LVL Other features: According to the results of the practice, it is believed that although some of the properties of the laminate is not as good as the material, but the veneer lumber its own defects (knots, cracks, decay, etc.) evenly distributed in the veneer (LVL), the average performance is better than the sawing of raw wood. 1, creep performance, veneer laminated material has good creep resistance; 2, anti-fire performance, veneer lumber (LVL) fire resistance is better than steel; 3, durability, veneer lumber (LVL) accelerated aging test occurred when the destruction of glue than the glue when the minimum damage;

The method comprises the following steps: the log is cut into a specification plate, and then the specification plate is cut into a single board; after drying, the resin paste is uniformly sprayed on the connecting surface of the veneer and aged; Layer of tile, and the carbon fiber layer between the single board layer; and then through the cold press pre-pressure, hot press hot pressing, the final split, chamfer, anti-corrosion to become the formation of veneer lumber.

Uses: LVL is mainly used for All kinds of packaging plants, wood products factory, especially machinery, glass, chemical and other products export packaging, in addition to a wide range of container mats, building template components, building beams, car panels, furniture, flooring , The room decorated wooden keel and so on.

| FACTORY PHOTO |

| FAQ |

| 1.Q:Are you manufacturer or trading company? |

| A:We are manufacturer locaed in Zaogoutou Industrial Park,Linyi city,Shandong province,we can help you book ticket and arrange you accomdation. |

| 2.Could I got a sample,before order?What is the delivery time? |

| A:We can supply you free sample before order,normally delivery time is 15-25 days depend on your quantity. |

| 3.What is your main market? |

| Up to now,we have exported country and region included(South-East Asia,EU,JAPAN,MID-EAST,SOUTH AMERICA,AUSTRILIA) |

| 4.What is MOQ?How many pcs can load in a 40'FCL,and how much of freight fees? |

| Normally our MOQ is 1 container,40'FCL can load 45 m3,we have our cooperated forwarding company,we can save much freight fees for you. |

| 5.Could you introduce your company to me? |

| A:Linyi mingsen Wood Co., Ltd. is a strong, technologically advanced professional plywood manufacturers, the company is located One of China's main origin Linyi city of Shandong Province. The company's main products are plywood, LVL plywood glued .LVB Board, packaging foot pier, Film Faced Plywood,Commercial Plywood,Melamine board, MDF , OSB ,and packaging shaped plate. The annual output of 100,000 cubic meters. |

| More question,please feel free contact with me by inquiry or follows information,we are gladly ready service to you! |

Contact us if you need more details on 18mm lvl Plywood For Furniture and door core. We are ready to answer your questions on packaging, logistics, certification or any other aspects about lvl plywood for furniture、Door Frame LVL. If these products fail to match your need, please contact us and we would like to provide relevant information.

Product Categories : LVL door core

Premium Related Products